What is behind the semiconductor production of transistors with dimensions of a few nanometers, from which chips for CPUs, GPU, SoCs and Co. are made? ComputerBase reader Christoph Riedel gives a well-founded overview of essential aspects and innovations in chip production.

Table of contents

- 1 Innovations yesterday, today and tomorrow

- About the content and author of this article

- A brief explanation of transistor, MOSFET and CMOS

- The goal of semiconductor manufacturing technology

- 2 Advances and innovations in manufacturing I

- The thickness of the insulating oxide layer

- The materials used

- 3 Advances and innovations in manufacturing II

- FinFET: transistors with fin structure

- Multipatterning: x exposure steps per layer

- The switch to EUV lithography

- Gate-All-Around: On the way to 3 nm

- Where is the journey going?

About the content and author of this article

This article covers both the relatively simple fundamentals of transistors as well as the various advances and innovations that have enabled significant improvements and will enable them in the future. Oxide thickness, materials, FinFET, multipatterning and gate-all-around. In the article From silicon to die: How chips are made from wafers in the clean room, ComputerBase author Thomas Böhm wrote about the basics of chip production.

As with the previous articles by Christoph Riedel, “What is behind EUV lithography” and “This is how beams are accelerated by GPUs”, the author has once again set himself the task of describing scientific findings in a comprehensible manner for a wide range of readers.

This text is based in part on an article in the Journal of Physics entitled Review of Modern Field Effect Transistor Technologies for Scaling, published by researchers at the University of Dublin last year and freely available.

The basis of all the technological advances discussed in the following is the transistor from which “chips” are made. A few more paragraphs should therefore also be devoted to the transistor.

Brief explanation of transistor, MOSFET and CMOS

A transistor is an electronic component that is basically an on/off switch. A control signal at the input, the base, enables a current to flow between the two outputs called collector and emitter or not. The English names gate, source and drain are often used for these three contacts.

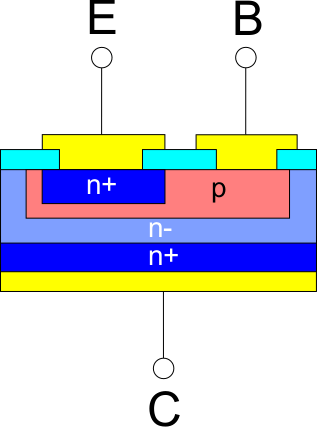

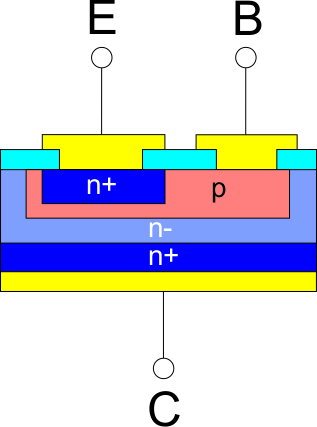

A simple transistor is the bipolar transistor, which consists of doped silicon, which has a higher conductivity than untreated silicon. Depending on the foreign material that is introduced into the silicon lattice, one speaks of n-doped (electron-rich) or p-doped (electron-poor) silicon. Bipolar transistors exist as npn or pnp transistors, the only difference being the direction of the current flow.

In the case of the npn transistor, a positive voltage is applied to the base, so that a small control current flows between the base and emitter. This current is amplified by the transistor by a fixed value, so that a larger current flows between the collector and emitter. The gain factor is determined by the external wiring with resistors. A bipolar transistor is thus an analog current amplifier, as it is still used today in audio amplifiers.

-

Schematic structure of a bipolar transistor with emitter (E), base (B) and collector (C). (Image: Wikipedia)

Schematic structure of a bipolar transistor with emitter (E), base (B) and collector (C). (Image: Wikipedia)

Image 1 of 2

Schematic structure of a bipolar transistor with emitter (E), base (B) and collector (C).

Schematic structure of a bipolar transistor with emitter (E), base (B) and collector (C).  Planar structure of a field effect transistor

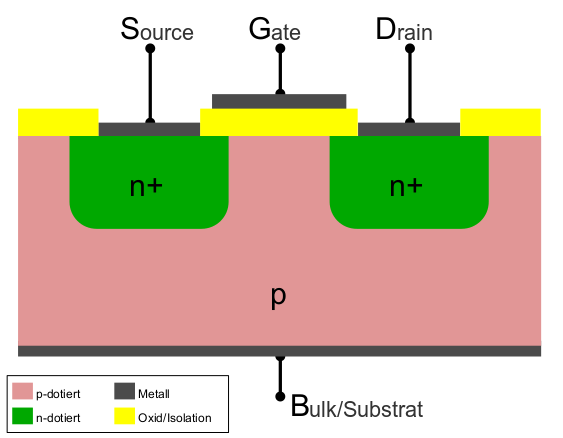

Planar structure of a field effect transistor Via MOSFETs to the CMOS

For digital circuits you need two clearly separated voltage levels for the values 0 and 1, e.g. B. 0 V and 5 V. A suitable switch changes back and forth between these two voltage levels and does not assume any intermediate states. In order to keep losses as low as possible, the amplifier should have a negligible current flow for the switching process, which excludes bipolar transistors.

These requirements have been met through the development of field-effect transistors (FETs) that operate with practically no current flow. The base of an FET is separated from the rest of the transistor by an insulating layer. If a voltage is applied to the base, instead of a control current flow, an electric field is created, which increases the conductivity between the collector and emitter. The FET therefore switches current-free. Since subsequent FETs also do not need a current flow to switch, it is sufficient to pass through the switching voltage of z. B. 5 V to operate entire circuits. A digital circuit consisting of a number of FETs is therefore theoretically lossless. The standard manufacturing technique for FETs consists of a combination of metals (M), insulating oxides (O) and semiconductors (S), which is why the technology for field-effect transistors is abbreviated as MOSFET.

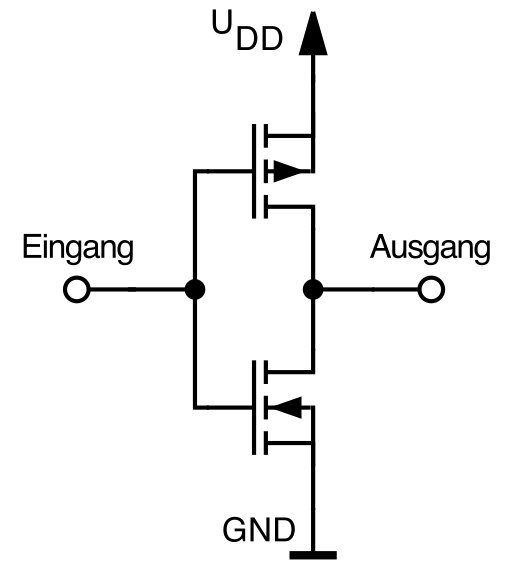

< figure class = "image__wrap" style = "max-width: 424px">  CMOS circuit, here as an example that of an inverter, from an n-FET and a p-FET (picture: Wikipedia)

CMOS circuit, here as an example that of an inverter, from an n-FET and a p-FET (picture: Wikipedia)

For a perfect digital circuit, however, a single transistor still has one disadvantage: when it is blocked, the voltage at its output is not clearly defined. It is not the 5 V of the supply voltage, because it is blocked, but it is also not exactly 0 V (GND), as a line with 0 V would have to be passed through for this. This ambiguity in the blocked state is resolved by combining two oppositely doped MOSFETs. In a structure made up of an n-MOSFET and a p-MOSFET, the first transistor works as described above, while the second transistor passes through exactly 0 V whenever the first one blocks. Since the two transistors complement each other, one speaks of “Complementary MOSFET”, or CMOS for short. The CMOS technology enables clean digital signals with particularly low energy consumption and short switching times.

On the basis of this knowledge, the manufacturing techniques and the functionality of modern CMOS transistors should now be considered.

The goal of semiconductor manufacturing technology

The goal of semiconductor manufacturing technology is the ever smaller production of field-effect transistors, which means that increasingly complex circuits can be manufactured at lower costs, because each exposed mm² costs on the wafer. Further advantages such as increased switching speeds and reduced power consumption by the transistors are secondary effects of improved production. ComputerBase created a detailed overview of the semiconductor production in the clean room a few years ago in a self-experiment.

The production by photo-lithography basically builds up a transistor from bottom to top. Compared to a bipolar transistor, the structure of a CMOS transistor in the lower layers is very similar. These areas are achieved through the different doping of the silicon. A lithography step consisting of the application of photoresist, exposure and development is necessary for each doping. The special difference with the FET is the integration of a capacitor-like structure on the base, which collects charge carriers above or below the oxide layer (depending on the voltage). This makes two further lithography steps necessary, in which, instead of doping, first the insulator and then the metal contact are applied.

On the next page: Progress and innovations in production I