NASA has successfully test flights were carried out with a plane that was equipped with welvingskleppen shape can change. Due to the lack of cracks and corners that arise in the unfolding of normal flaps, the aircraft must consume less fuel.

The butterfly valve is developed by the company FlexSys and is supported by the Air Force Research Laboratory. NASA is also a partner in the research programme, which is more environmentally friendly aircraft must deliver.

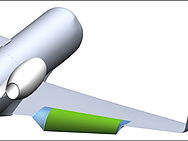

Virtually all airplane wings are equipped with welvingskleppen or flaps to the surface of the wing to increase, so the lift force increases. Extended need the plane less speed to make it before it gets off the ground. On the other hand reduces in the collapsed position, the aerodynamic drag, giving the aircraft in cruise uses less fuel. Flaps are deployed, however, aerodynamically not optimal, due to the sharp corners and crevices which are formed in the wing area. That leads to a higher fuel consumption, while also the noise increases.

After wind tunnel tests and previous test flights with the White Knight, the plane of Scaled Composites that the SpaceShipOne aircraft launches began in november 2014, a more detailed vliegtest with flexible flaps. Before that, a Gulfstream-III aircraft from NASA adjusted. The six-foot-long conventional flaps were removed and replaced by flexible flaps. This FlexFoil-valves are made of materials which are normally also in the aerospace industry are used.

FlexSys has worked for more than fifteen years, materials that can bend. They are flexible by the internal structure, the stress of bending distributes the material. Therefore, the flaps according to the company to remain flexible without that fatigue strength losses. FlexSys promises a reduction of five to twelve percent aerodynamic drag for a large aircraft, while the noise during the countries, even with forty percent must decrease.

The 22 test flights in the last six months were carried out, mainly had to prove that the technology is mature enough to be airworthy. The skirts were to do so in all positions tested, at an angle of -2 degrees to 30 degrees. All tests were successfully completed.