The utilization of TSMC's factories could drop to around 80 percent in the first half of 2023, only to increase again thereafter. However, this does not apply to all areas, with the most modern processes such as N4 it remains at almost 100 percent. This is another reason why the expansion plans continue unchanged.

TSMC's Fab 18 is the current gem of the world's largest contract manufacturer. Several phases, as the manufacturer calls its expansion stages, which alone could almost each be a fab, are already online, and there should be up to nine phases in the end. TSMC currently manufactures N5 and N4 chips there, and will also manufacture N3 and N3E in the future. So far, eight construction phases have been presented, which can also be clearly seen from a bird's eye view on Google Maps. Together with Fab 14 and its eight phases and packaging fabs, the complex is one of the largest in the world.

-

TSMC Fab 18 Phase 8 under construction (Image: DACIN Construction Co., Ltd.)

TSMC Fab 18 Phase 8 under construction (Image: DACIN Construction Co., Ltd.)

Image 1 of 2

The Fab 18 will not have any real utilization problems in the near future either. Because the N5 process offshoots such as N4, N4P and more determine the timetable for the high-end business, N3 will follow as a new solution from 2023, even though the order situation for this does not look so rosy at the moment. Increased demand is not expected here until the end of 2023 with N3E.

The problems with utilization are more likely to be in older plants and older manufacturing processes, DigiTimes again reports. The 7 nm production in particular was recently identified as the biggest problem child, the high-end clientele has switched to the N5 and N4, and follow-up orders are not filling the large capacities there. The tense economic situation with inflation and downturn does the rest. TSMC does not expect any improvement here until mid-2023, the manufacturer recently officially stated.

But the other older production processes should also be less in demand in the first half of 2023 than they were recently. This also applies to the nodes in 40/45 nm and 28 nm, which are heavily used by the automotive industry, for example. In the intermediate step down to the most modern processes, 12/16 nm, the decline should also become clear. However, nothing will change in plans for the future, TSMC told news agencies, including the outcome of local elections in Taiwan Make effective use of off-peak hours

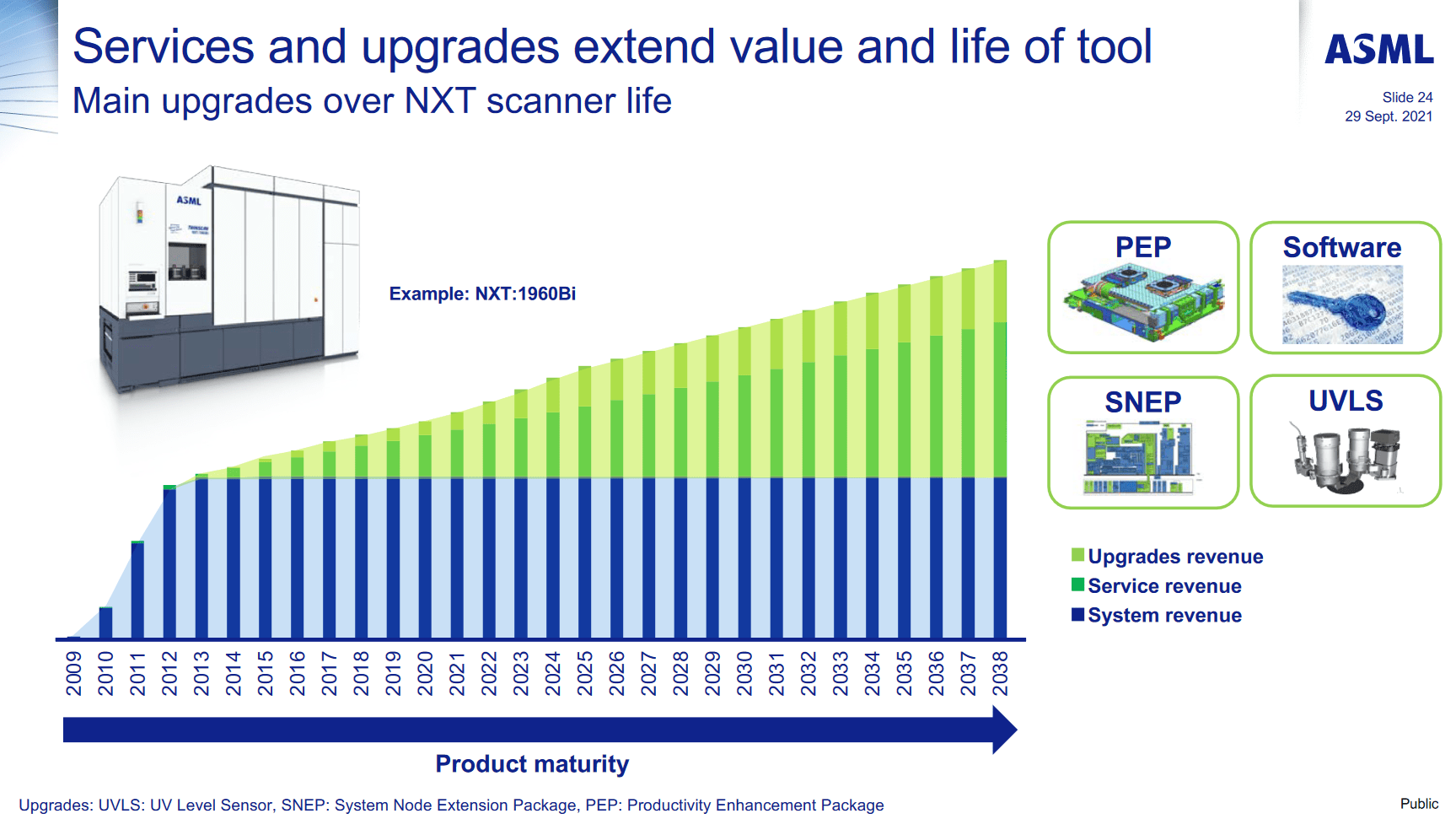

In previous years, TSMC used the regularly occurring lull in the first half of the year to bring forward maintenance on the machines and, for example, to carry out repairs and improvements. The bottom line is that the total available capacity has changed, and the utilization of the existing systems remains almost at the (lower) maximum. If this can reasonably be planned for, TSMC should now proceed in a similar way. For example, modern exposure systems from ASML can be upgraded to a better model within a few weeks, ultimately further increasing the capacity and efficiency of a factory.

-

Upgrades in the field within six weeks (Image: ASML)

Upgrades in the field within six weeks (Image: ASML)

Image 1 of 2

Classic scanners can and will work for decades constantly improved (image: ASML)

Classic scanners can and will work for decades constantly improved (image: ASML)After the constant stress of the last two or three years, TSMC had already increasingly encouraged the employees, yes to take and enjoy their vacations. Because the next phase of the boom for TSMC is definitely coming, the industry giant is self-confident.