The automotive supplier Bosch is together with a Swedish manufacturer in a large scale in the development and production of fuel cells. In three years, the market reaches maturity.

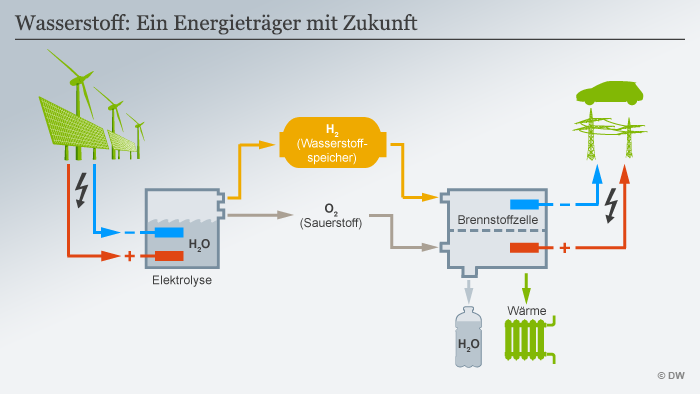

Together with the Swedish manufacturer power cell, Bosch wants to bring so-called Stacks, ready for series production and then for the global market to produce, as it is called in a message from Monday. The Stack is the heart of the fuel cell, in which hydrogen is converted into electrical energy.

“Bosch is in the market for mobile fuel cells and promotes the industrialization,” said Stefan Hartung, head of the car division Mobility Solutions. Fuel cell systems with the self-made Stacks want to bring Bosch, therefore, at the latest in 2022 on the market.

Although the fuel cells is currently prohibitively expensive, Bosch a market breakthrough. By 2030, up to 20 percent of all electric vehicles could be powered in the world with fuel cells, the group estimates.

First of all, intended for commercial vehicles

The best chances of the supplier looks for the time being, in the case of commercial vehicles. For a nationwide application in the passenger Car segment should be the technique is initially effective. Bosch works in the USA with Nikola motor, in order to develop trucks powered by fuel cell.

Last year, the supplier also entered into a cooperation with the UK company Ceres Power for the development of small fuel cell power plants to advance – there is an other technique is based on but. Bosch had thought about for a long time, to self-produce battery cells for electric cars, from the Plan, however, for reasons of cost adopted.

According to estimates from Bosch, the drive technology can be in the future, but also for Cars cheap enough. This includes the Stacks, the heart of the cells, and the hydrogen would have to be even cheaper. For example, hydrogen, a 40-ton Truck consumes 100 kilometers Bosch, today, even more than 50 euros. “Due to the industrialization and the dissemination of the technology on the market, Bosch will achieve economies of scale and the Costs,” said Hartung.

Of the battery cell manufacturing adopted

For the world’s largest automotive suppliers and its customers, the decision of Bosch to mass production is strategically important. Currently, the car manufacturers prefer under the pressure of stricter climate protection regulations in Europe and China, the developed, comparatively cheaper batteries for electric drives. Volkswagen-chief Herbert Diess was required to concentrate on this technique.

Also, Bosch wants to be in this field of leading suppliers. However, the Swabians had not decided differently than now, in the case of the fuel cell, – after a long examination, to develop the essential components of the battery cell, and manufacture. In order to assert itself against the established competition from Asia, would have Bosch must according to their own figures, around 20 billion euros to spend. Investment costs of the cells for the fuel systems made by the group. To power cell flow for the cooperation of a medium two-digit million amount. Added later, a license fee per sold Stack.

The hydrogen filling station network in Germany with 60 stations still manageable, the tendency is, according to Bosch, but rising. Will the hydrogen within a few minutes as a highly compressed Gas.

hb/ul (dpa/rtr/afp)