The community from the ComputerBase forum demonstrates how a compact housing is created with the help of a 3D printer, lots of mesh and your own ideas. At the end of the first “expansion stage” there is an airflow case measuring 130 mm × 360 mm × 280 mm (W × H × D) in microATX format, which can be easily adapted.

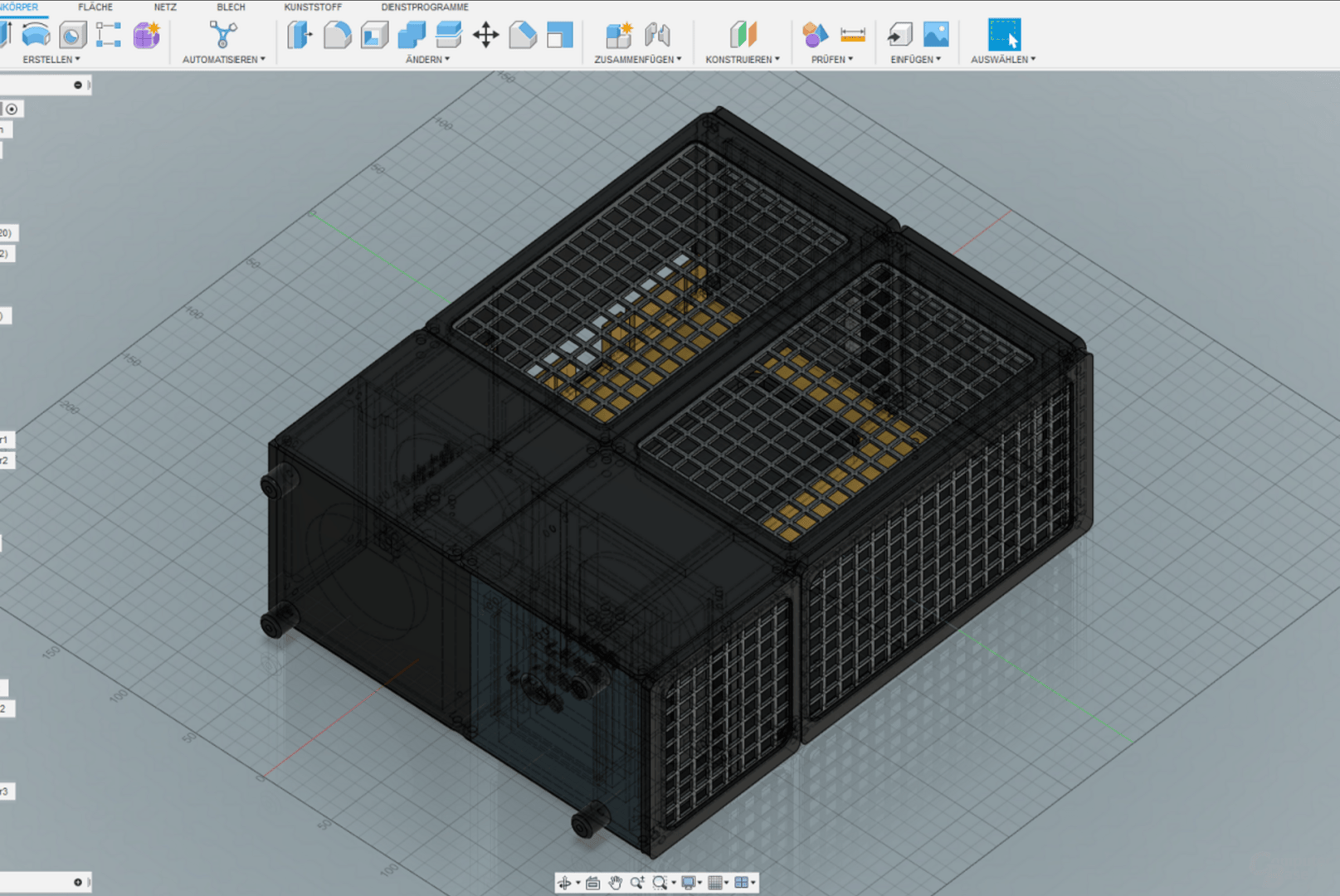

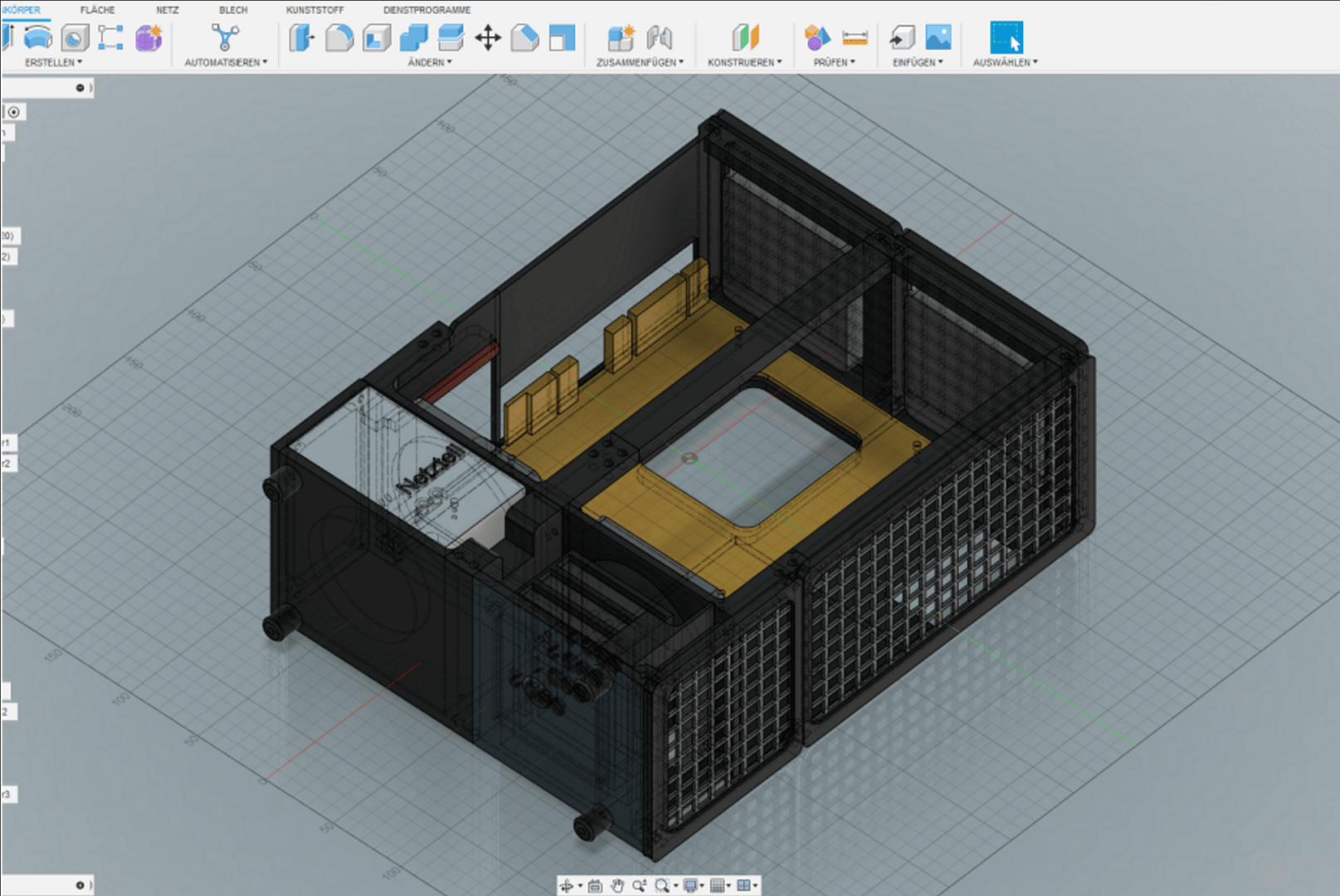

In his reader article designed as a project “My case from the 3D printer”documents the ComputerBase reader “an.ONE”, who has been actively involved in the community since 2004, how he (his) planned a very individual microATX case and was able to realize it with the 3D printer. The planning started in the professional CAD, CAM, CAE and PCB program Fusion 360 from the US software developer Autodesk with the following goals: upgradeability and adaptability.

The drawing of the case in Autodesk Fusion 360

Individual, adaptable and upgradable

In his reader's article on the project, the author describes his motivation for the compact, self-assembly case as follows:

Since I wanted to challenge my 3D printer a bit, I decided to print an ABS case and then use it for my daily PC.

Since I own several printers and don't like to wait long, I cut all the models for a build space of 220 mm × 220 mm and then glued the parts with acetone.

That I had planned the whole thing for a long time, now finally the beginning of the implementation.

an.ONE, community member

In addition to the numerous self-construction elements from the 3D printer, a set with 400 mm × 300 mm from Amazon was used as a mesh insert. It's all reinforced with an ABS inlay in a grid pattern to keep the mesh from collapsing.

- Reader article: My case from the 3D printer [project]

Further expansion stages are planned

The interior of the microATX case offers space for mainboards with an edge length of up to 244 mm × 244 mm, while installing a total of four 92 mm fans and other upgrades are already on the author's to-do list.

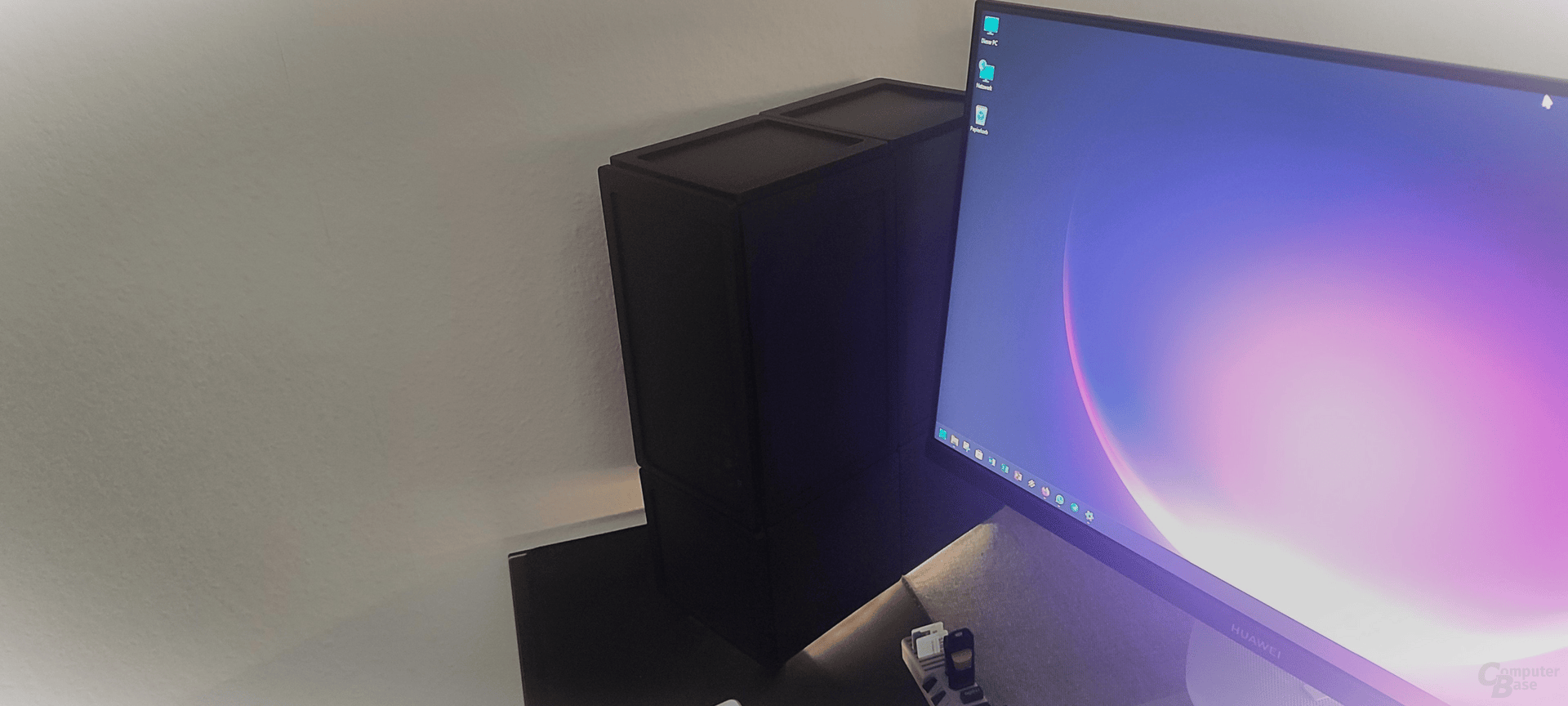

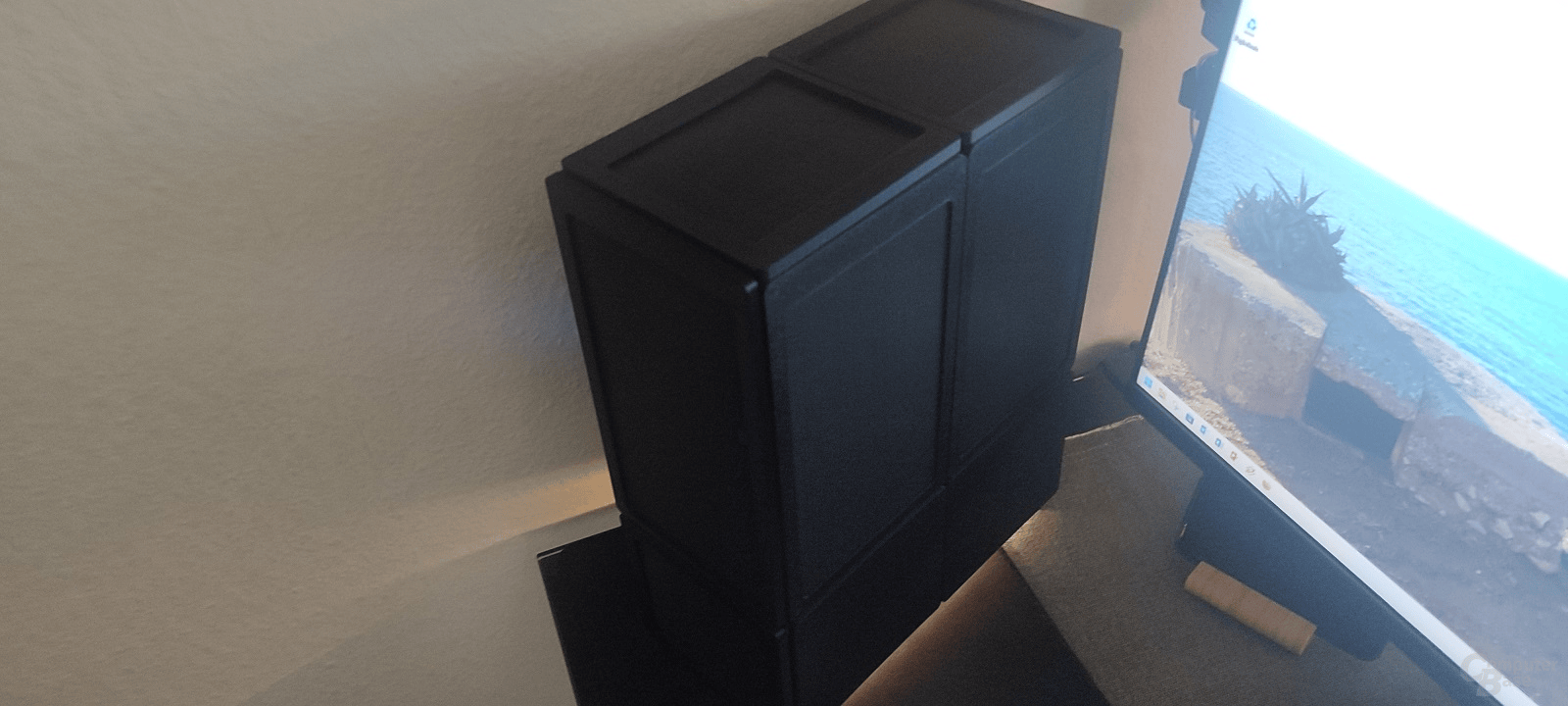

The airflow housing from the 3D printer in the first expansion stage

Many more photos of the self-construction elements from the 3D printer and the production process can be found directly in the reader's article. These should not be anticipated at this point. The author also provided information when asked by the community which setup he uses on 3D printers.

I'm currently using six small Elegoo Neptune 2S with a little conversion and WLAN upgrade and have a Tronxy X5SA-400 with the same for larger components some modifications, but it doesn't run 24/7.

None of these are high-end printers, but reliable and inexpensive printers for small series production. Three of them are housed in my foosball table, the others are all in the basement.

an.ONE, community member

Like such a self-construction from the 3D printer including the installed hardware is also clearly demonstrated in the reader's article.

DIY from the 3D printer with installed hardware

DIY from the 3D printer with installed hardwareFeedback expressly desired

Questions and suggestions as well as praise and criticism on the topic are welcome in the comments this message, as always, expressly desired.

The author and the editors look forward to hearing about your point of view first-hand.

Bring on the hints!

In the “From the community” category, the editors repeatedly focus on interesting reader articles from the ComputerBase forum.

The following reader articles from the ComputerBase forum have recently been published secured a place on the homepage:

- Cooler FAQ

- Sunon Waturbo

- AMD Radeon RX 6400

- AMD Radeon RX 6900 XT

- GeForce 4 MX 4000 with OC

- The Airbus A320 home cockpit

- Nvidia GeForce FX 5200 im Reader test

- Ryzen 7 1700X and two Xeon X5460 in a CPU duel

- First-hand experience reports on the Steam Deck

- Mini-ITX power dwarf: AMD Radeon RX 6900 XT and AMD Ryzen 9

- K7 and Voodoo²: A journey back in time to the old days

- AMD, Intel and Nvidia: The ideal gaming PC

- Arc A380 vs. GTX 1650 vs. 6500 XT

The editors would like to thank community member “fanaticmd” and forum moderator “burnout150” for the tip e to this message from the ComputerBase forum.