The roads , we know well, age quickly and require frequent maintenance that does not it only creates inconvenience to traffic, but represents a important cost item for public administrations. Not to mention the patches that are applied to the holes (sometimes real chasms) that are created especially after the winter season, between the spreading of salt to prevent the water from turning into ice and the passage of heavy vehicles, 365 days per year. There are plenty of projects and experiments to improve the state of the roads – see LIFE NEREiDE, tested in Tuscany a few years ago – but none of these, so far, has taken into consideration another factor that negatively affects the state of health of the # 39; asphalt: the sun. UV rays cause cracks and breaks, and roads all over the world are subject to this risk as they are made of material unable to protect them.

AN ASPHALT WITH TIRE RUBBER

Filippo Giustozzi, Associate Professor at RMIT University in Melbourne. Credits: RMIT

RMIT University – Royal Melbourne Institute of Technology – has developed a new type of asphalt capable of withstanding both truck stresses and potential damage caused by the Sun . To the classic bitumen & egrave; a was addedrubber mixture extracted from used tires : the result is; surprisingly, the roads in this way manage to even last twice as long . The special & quot; sunscreen & quot; ago s & igrave; that the road is more & ugrave; resistant to parity; of other conditions – can not & ograve; for example being too soft. In practice, until now we had concentrated on resistance to atmospheric events, thermal variations and traffic load, but the possibility had never been evaluated; that UV rays lead to premature aging of the road surface.

Therefore greater safety and a much longer duration compared to the current average, as well as; – not negligible fact – advantage in environmental terms as it is & egrave; able to recycle material otherwise difficult to dispose of. The results of the laboratory experimentation were published in the Journal of Cleaner Production. These are the words of Filippo Giustozzi, associate professor of RMIT University and first signature of the study:

We have found that the aging trend is actually slowed down when crumbled rubber, recycled from scrap tires, is added to the top layer of a road. This acts like this; effectively as a sunscreen for the streets that actually makes the surface last twice as long as normal bitumen.

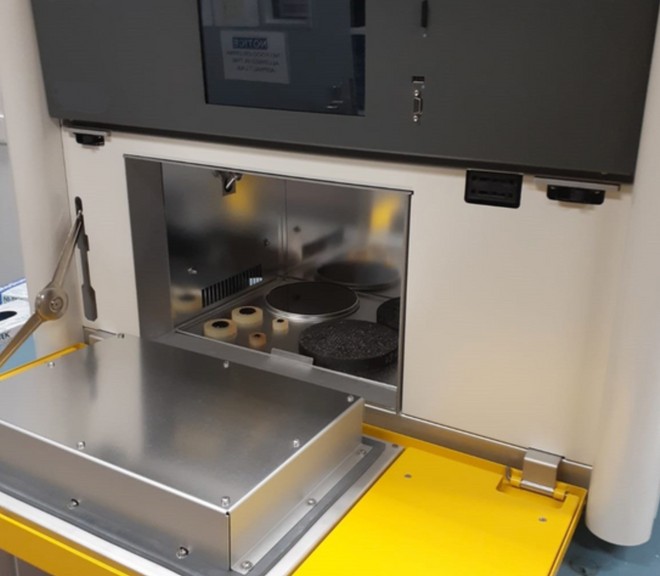

The UV machine of RMIT University. Credits: RMITUNA RIGHT DOSE TO GUARANTEE SAFETY

The UV machine of RMIT University. Credits: RMITUNA RIGHT DOSE TO GUARANTEE SAFETY

Different percentages of rubber-bitumen mixture were simulated in the laboratory, from 7.5 to 22.5% . One and a half months of exposure to the university's UV machine (hitherto used for other purposes, such as to assess the resistance of outdoor furniture paints) corresponds to one year of UV radiation in the city & agrave; of Melbourne. After this period the variations of the properties were analyzed; chemical and mechanical properties of the compound , and & egrave; It was verified that the mixture was able to halve the damage from ultraviolet rays compared to traditional bitumen.

The best rubber-bitumen balance that guarantees protection from UV rays and safety for means of transport provides for the 39; I use between 18 and 22% of rubber crumb . And the best part, says Professor Giustozzi, is; that many roads already; they have a small percentage of tire rubber inside, but no one until now had understood that this could also bring benefits from the point of view of protection from the sun.

Credits opening image: Pixabay

The best Xiaomi for photos without 5G? Redmi Note 10 Pro, buy it at the best price from Amazon Marketplace at 399 euros .