The display manufacturer Japan Display Inc. (JDI) has developed a process that eliminates the need for fine metal masks in classic OLED production. This should massively increase the efficiency of the OLEDs and also protect the environment.

Without mask

The so-called fine metal masks (FFM) are currently the primary method for evaporating organic material for the mass production of OLED displays. With the eLEAP process now presented by JDI, on the other hand, FMMs are completely dispensed with, which is a first in the industry. The manufacturer also speaks of a “historic breakthrough” in the performance characteristics of displays.

According to JDI (PDF), the abbreviation eLEAP stands for the following:

e nvironment positive Lithography with maskless deposition Extreme long life, low power, and high luminance Any shape Patterning

OLEDs shine more efficiently

The new technology should allow the RGB pixels to be structured more precisely. As a result, the ratio of the light-emitting area to the total area of a pixel, the so-called aperture ratio (also called emission efficiency by JDI), is roughly doubled compared to the previous method: According to JDI, the emission efficiency of the FFM method is only 28 percent and that of the new eLEAP procedure 60 percent.

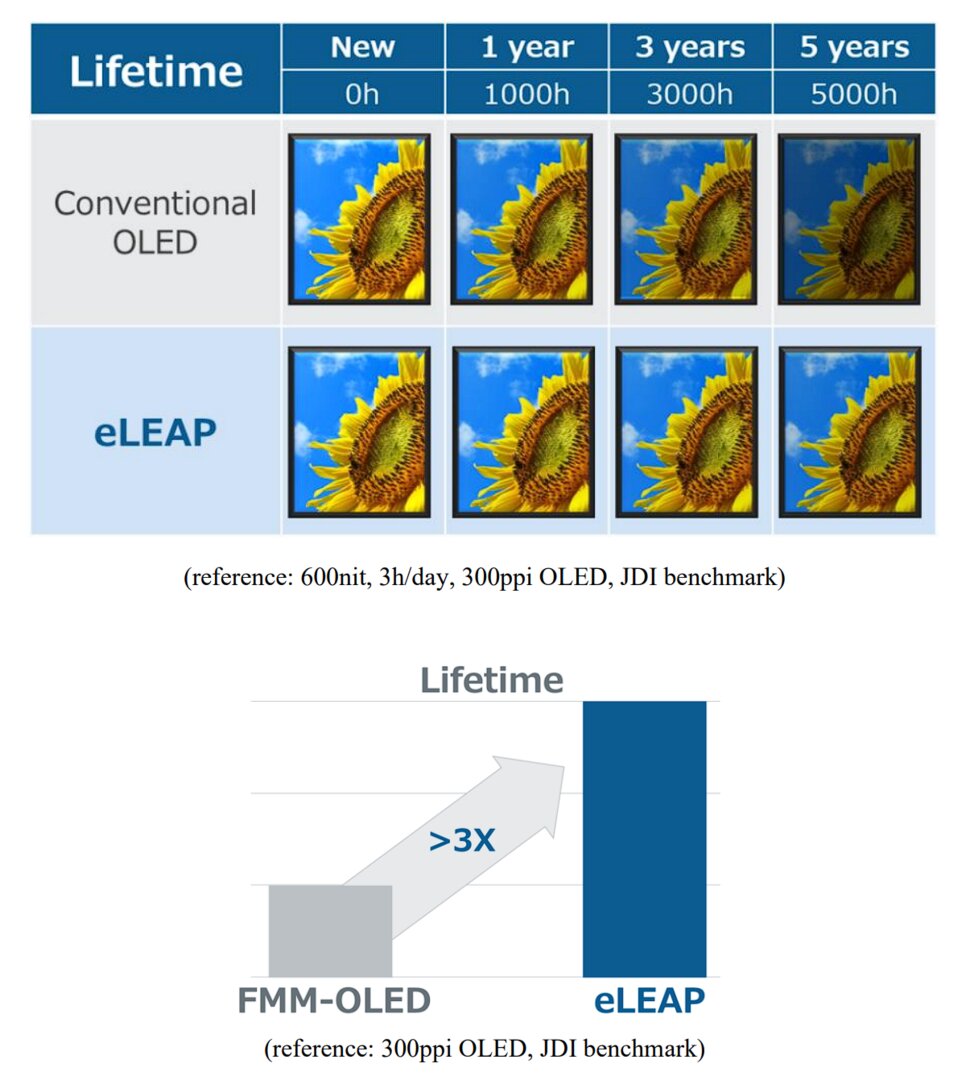

With the same brightness, less power for a longer service life (Image: Japan Display Inc. (JDI))

With the same brightness, less power for a longer service life (Image: Japan Display Inc. (JDI))This in turn requires less power for the same brightness, which in return should ideally triple the lifespan of the OLEDs. The other way around, the maximum brightness can be doubled.

Production is more economical without metal masks

The omission of metal masks also ensures more environmentally friendly production, since some cleaning processes that would otherwise be necessary are no longer necessary, which also reduces costs. In addition, the size and shape of the OLED display are no longer dependent on the mask, so there is more flexibility here.

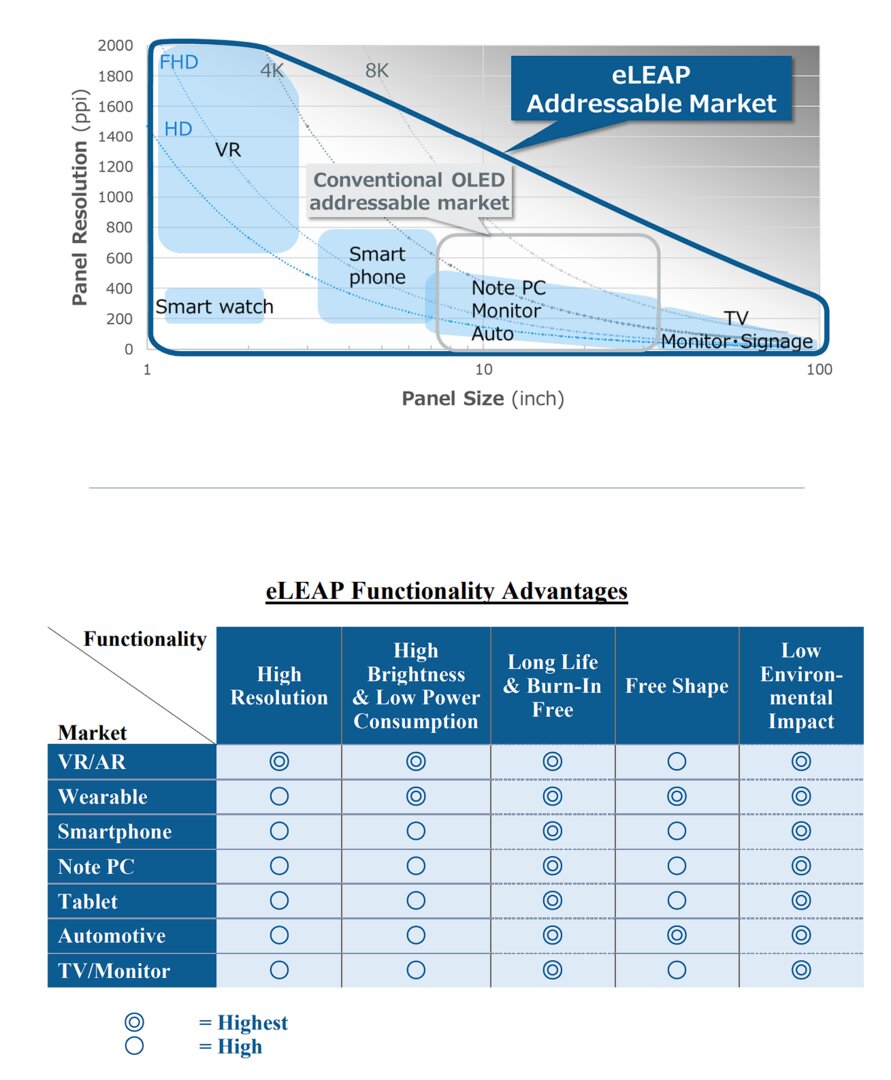

Areas of application and advantages (image: Japan Display Inc. ( JDI))

Areas of application and advantages (image: Japan Display Inc. ( JDI)) According to JDI, the conventional FMM method is limited to glass substrates of size G6 (approx. 1500 × 1850 mm), with the new eLEAP method one can use up to G8 (approx. 2200 × 2500 mm) or go beyond. The spectrum of possible products ranges from tiny wearable displays to large-format 100-inch televisions.

Patterns must first prove themselves

The technology is well received by potential customers, writes JDI and wants to start with sample production in the course of the year. The company will probably not only keep the technology for itself, but also make it available to other display manufacturers.

eLEAP is a historic breakthrough in display technology that is vastly superior to current OLED technologies. JDI is already in discussions with customers and has generated significant customer interest, with customer demand expected to grow rapidly over time.

JDI

Whether JDI the big ones Can keep promises with the first samples remains to be seen. Brightness and lifespan address two major weaknesses in traditional OLED displays. It seems almost too good to be true that the costs should be reduced and the environment protected at the same time.