Implants, prostheses, and medical tools need machines on which they are made. The demand is increasing and so more and more machine-builders in the growing field of medical technology to try to gain a foothold.

Replacement teeth that look exactly like the Original. Bone screws, the broken bones to stabilize, but no longer out of surgery need to be, because they degrade at the same rate biologically as the boil heals. What brings people relief for businesses is a big business. In the health sector have been implemented in the past year, nearly 370 billion euros, the equivalent of twelve percent of the German gross value added. And the industry has grown in the last ten years, with about four percent per year, more than the entire German economy, the German medical technology Association (BVMed).

A part of the healthcare industry, the medical technology is. It is relatively independent of the economy, because there will always be broken joints, hips and teeth. In addition, demographic change will provide for additional revenues. We are more and more people in the world, which also means more and more potential patients. More patients also the demographic development in Germany. Even if it may seem cynical sound: Older people need more spare parts as a boy. Alone in 2016, were implemented on the implants market in the world, over 40 billion US dollars.

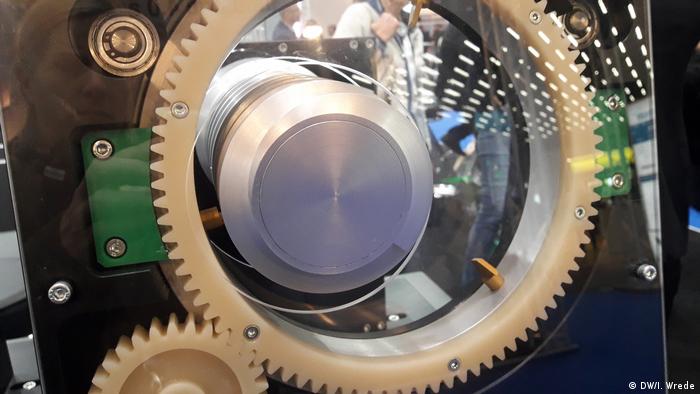

A enlarged model shows how to screw (in the middle) better machined can be

More and older people to ensure steady growth

On this growth, more and more machine builders are now using. So far, the German machine builders have lived well from their main customer, the automotive industry,. The is now but before the huge upheavals because of the need to change to protect the climate, the mobility and electric, many of the components, such as transmission vehicles cease to apply. The same is true of the suppliers, the machinery and machine tool manufacturers. And nobody can really tell where the journey goes and what machines will be needed in the future. In addition, the mechanical engineering suffers as a classic export industry, under the stuttering world economy, which is the result of Brexit and trade dispute out of step.

Quite simply the cream can be in medical technology, but not skimming. The fact that more and more of the market would urge participants in the market, increases the cost pressure and the need for more efficient processes and machinery, says Marc-André Dittrich from the Institute for machine tools and manufacturing engineering of the University of Hannover.

The mechanical engineering provides: the machines are assembled and programmed, that they can produce medical parts around the clock – without people continuously supervised

Also, the documentation and reporting requirements that must be fulfilled by manufacturers of medical devices and implants, become more and more extensive. And with them the demands on the machines that need to provide such data. In addition to new materials, the development of new machine tools and procedures required.

Printing human spare parts

One such new method of 3D printing. Better, faster and cheaper it can be, for example, the treatment of patients with bone cancer in the face, it is called by the machine manufacturer Trumpf. This cancer must be removed, under certain circumstances, parts of the bone from the face. Then replaced the missing tissue, have Affected a life with a horribly disfigured face in front of him.

Therefore, surgeons try to replace the missing bone mass in a way that the face looks about the same as before. The doctor had to cut so far during the Operation, the implant made of a titanium perforated plate.

Everything from the 3D printer: front hip implants, behind it, a face implant and, behind it, printed teeth. The need to be of the round carrier plate is cut off and ceramic coated

Before the Operation, the data to the facial form of the patient can be determined. It is digitally created, a implant, and printed. In Operation, the implant is then in the proper Form and cleaned up for the doctor of Europe. Thus, the duration and the cost of the Operation will be reduced.

This method uses the Russian manufacturers of medical technology CONMET since the beginning of 2018, to 3D printers, trump customized facial and jaw implants can restore. Is printed metal. In a machine using a Laser metallic powder is melted to form a material layer. Then a new layer of Powder is brought about, which, in turn, is melted, and so on. With this method, geometric spaces of complex shapes with hollow interior lattice structures that you could not make with conventional methods such as milling at all.

3D printing: metal powder is melted by a Laser, to print implants

Dentures out of the printer

The 3D printing technology also helps many people who do not develop cancer, but just have a Tooth lost. So far, teeth have been milled, which means a Block as long as cut off a bit, until the Tooth had been shaped out. Teeth from the 3D printer, not only look like the original tooth, they are also cheaper and faster, says Neumann. “In some markets, are now printed 80 percent of the crowns 3D, for example, in Spain. In Germany there are around 20 percent, but that is a piece more,” says Neumann.

Printed saws, the cool

The mechanical engineering doesn’t care but only to the perfection of human spare parts, also during the Operation the instruments used are getting better and better. 2016 joints were in Germany, 230.000 knee and 165,000 hip joints implanted. Such implants use must be sawed off a piece of healthy bone.

“The difficulty is that as with any mechanical separation process, friction occurs, which in turn generates heat,” explains Marc-André Dittrich from the Institute for machine tools and manufacturing engineering of the University of Hannover. The heat is too big, the cells die in the existing bone so that the implant adheres properly. If then a second Time to have surgery, the Patient suffers from, and additional costs will arise again. “This is why we have developed together with two companies of new saw blades with internal cooling”, says Dittrich. And also this saw printed sheets.

The conclusion of the experimental rabbits man

If a Pilot learns his trade, then he is placed in a flight simulator. Also, Doctors can practice for 25 years in simulators operations digital. However, only for minimally invasive surgery. But anyone who wants to learn how to use a hip implants, practicing first at the pig, then corpses and finally on real patients, of course under the guidance of an experienced physician. Nevertheless, would hardly be someone who is a doctor makes the hip replacement surgery for the first Time on a live person.

“There is no digital Exercises, because you have to simulate large forces. If the Doctors milling around the hipbone, lean properly with your body to the weight,” explains Mario Lorenz, a researcher at the Technical University of Chemnitz. “That’s why we started three years ago, to deal with it ourselves, and have a Kuka robot used for this purpose – some purpose entfemdet – in order to allow the surgeon to feel the power”.

In such simulators for hip surgery one day Doctors can practice their craft

The doctor-to-be looks through a 3D glasses a Hüftoperations patients in an operating room. In one Hand he holds a real milling machine, which is connected with the robot arm. By the robot-generated resistance, the doctor gets a feel of how the surgery feels, how much pressure he must, for example, applying the reaming of the Hip bone.

Still, it remains, however, when Practicing on live people, because there is not such Hüftoperations simulators to the universities. Lorenz hopes, however, that this will change in the next two years.