Industry 4.0 – the digitalization in enterprise works only when the employees are taken. For smaller companies, often a big hurdle, because training must also be done.

“In a manufacturing operation like ours, it is also not so neat, but by the digitisation of up to 40 percent more efficiency, you can still get out,” believes Thomas Besse. For example, on the topic of media breaks. If an order arrives online in the company, he is digitally available, but must be printed for signature and then re-scanned.

Such fractures have to could work to be recognized, and must also be considered, “where individual departments meaningful to each other,” says Besse. He heads the IT Department of a Small metal-forming technology in Netphen. The family-owned company with around 300 employees, manufactures metal structures for car seats, brake parts for trailer or blades for camping heaters. The digitisation of better driving, the computer scientists in the last year for the “Digital Scout” form, in SMEs, 4.0.-Competence Centre Siegen.

Training of 4.0 across all industries

There he attended the Workshop series for employees of small and medium-sized enterprises (SMEs). The competence centre is a consortium of the University of Siegen, the South Westphalia University of applied Sciences, the Ruhr-University Bochum and the Fraunhofer Institute for Applied information technology (FIT). It is part of the Initiative “Mittelstand-Digital” of the Federal Ministry of Economics and works with SMEs in South-Westphalia, supports you with experts, network contacts and demonstration centers for the latest technologies. The services are free of charge.

Thomas Besse, Digital Scout, and head of the IT Department of the Small forming in Netphen

In the training round, the representatives of various industries and sizes of companies are to be found: As a pharmacist sitting next to a craftsman, or in addition to a Manager of an automotive supplier. In six months, the future of Digital Scouts met in the evening to five Workshops with lecture and work in small groups.

Most of the topics were not predetermined by the scientists, but rather jointly determined. So it could be edited, which burned to the participants in the most under the nails. In addition, the researchers benefited from them, to learn the needs of SMEs first-Hand.

At the company Klein Umformtechnik in Netphen, a camera scans the welded Spots. No man can for hours on the same parts of concentrated check.

Shiftplanning App

“Even the Smallest of learning,” says Besse. He had, for example, during the course, the idea to digitize the layer of planning. Who fails because of doctor’s appointments or child care, had to report to date the foreman. The organized then the exchange of the layers.

In the future, the System should inform yourself all of the matching operator. So you can swap even in the short term the layer. “How many employees should be in which layer, on an algorithm mapping,” says Besse. “The crucial thing is not who it is, but that the qualification is true”. If there is an Emergency, it would be about the App in addition to a Pool of pensioners or students to draw, without a switching company.

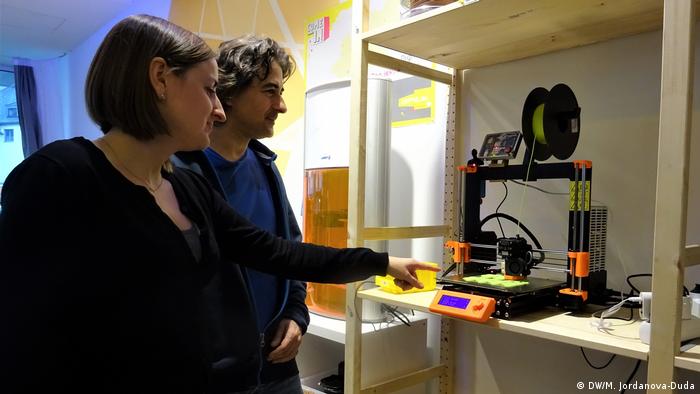

Such ideas, Scouts swap to continue, after the completion of the training with each other. Via an Internet platform, you can stay in touch and plan activities. About a visit to the learning factory at the University of Bochum, or in the FabLab of the University of Siegen, and various 3D printers, glasses Data, and to test a CNC milling machine.

“We can’t deliver within a few hours, the digitalization in the business,” says Marc Gerbracht, which is in the competence centre for the Digital scout in charge: “We can open the eyes, the tool show, and then we stand with advice and act to the side”.

In the FabLab of the University of Siegen, a 3D printer can be inspected at work

Training by the machine manufacturer Trumpf

“The machines are always connected and so must be from the machines process servers Manager”, is Gerd Duffke convinced. The former General works Council Chairman at the machine manufacturer Trumpf in personnel development for special projects. Because trump have a large number of SMEs as a customer and they would have no great capacities for personal development, he initiated the course “F4DIA”, “multiplier for the digitized world of work” training.

The Participants are composed of trump employees, and employees of the customer. “As multipliers to go with the glasses of the staff developer by the operation, and to explore how the processes and tasks change on the workstations,” said Duffke. It is important that they come about from the sales or production, because then they witnessed the change first-hand.

How the change can look like? “A service technician can do thanks to the digitisation of about a fifth of the work from home,” says Duffke. Service and repair instructions in real time thanks to data glasses and Headset, expensive and time can replace time-consuming business trips.

The course was designed with several partners. In the end the participants write a short work to a theme from your operating practice, in a guide. “We have made a kind of cookbook with various learning formats, and suggestions”, so Duffke. Methods such as Hackathon, Barcamp and Visual Storytelling are presented. It would, for example, how to win learning weaned colleagues, and how the multipliers in the follow-up support could ask. The digitization pioneers have created, Duffke, a What’s App group and help each other.