Mechanical engineering

Machine tool manufacturers reinvent themselves

The German machine tool builders are one of the five largest sectors in the mechanical engineering. However, they face major challenges, as technologies and markets change.

The German machine tool manufacturers to provide production technology for Metalworking in all branches of industry and in the whole world. Through their key position for industrial production is an important indicator for the economic development of the entire industry: the machine Tool builders, well, it’s the entire industry. In 2015, the industry produced about 68 500 employees, machines and services to the value of around EUR 15.1 billion – an increase of four percent compared to the previous year.

One of the major tasks for the near future, the sector is in the development of new growth markets. Currently, there are very strong shifts in their export markets. China, since 2003, by far the largest export market for the German manufacturer, with a share of, at times, up to a third, loses weight. The hope for the reindustrialization of the United States with high investments in production technology has not yet been fulfilled.

The editorial recommends

Industry 4.0: What’s coming on the people?

Break through the industry 4.0: What are the requirements for companies and their employees is important? This question tries to answer in a new study. (18.05.2016)

Machine builders only abroad

The demand for large-scale systems “Made in Germany” increased in March, surprisingly strong. Reason to hope for a reversal of the trend, the industry Association VDMA does not see yet. (02.05.2016)

Slight recovery in the mechanical engineering

After a weak start to the year, the German machine builders have brought in more orders. A mood of optimism, however, would be no speech, warns the industry Association. (04.04.2016)

Europe, again more in the Focus

Russia, for many years the third largest market, will take on this role in the foreseeable future. “Europe is therefore increasingly in the focus of German companies, because the European customers are faced with high quality requirements in the world market and invest,” says Heinz-Jürgen Prokop, Chairman of the Association of German machine tool factories (VDW) in December, the 125-year-old.

Promising, however, especially in the Asean Region and India, according to the VDW. They offer great potential for the machine tool industry. Here, it is important to convince the customers with better Offers and the leading competitors, Japan has consistently been the market share from. “That means more involvement, more presence, more investment and, where appropriate, also more cooperation, in the case that a medium-sized company can not manage everything that is Required alone,” says VDW Chairman Prokop.

The automotive industry is changing

Prior to a change in its business models with a strong impact on the production supplier to the automotive industry, the largest buyer of machine tools. The Central topics of technological change from combustion engine to alternative forms of propulsion, as well as the networked and automated Driving. New, non-industry competitors like Tesla and Google enter the market. In addition, new Services for customers, such as Car-Sharing models. Digitization and networking make it possible. “This development we must keep in view,” says Prokop.

Over 125 years the German manufacturers have developed their technology further and further and optimized. Therefore, you are in the world today. Given the high level of technical Mature degree of machines is a further challenge in the expansion of the service consists, however, offer enhanced customer benefits. “Success will remain in the world market only if the products continue to be the technology leader and further developed and additional services will be added”, is Procopius convinced.

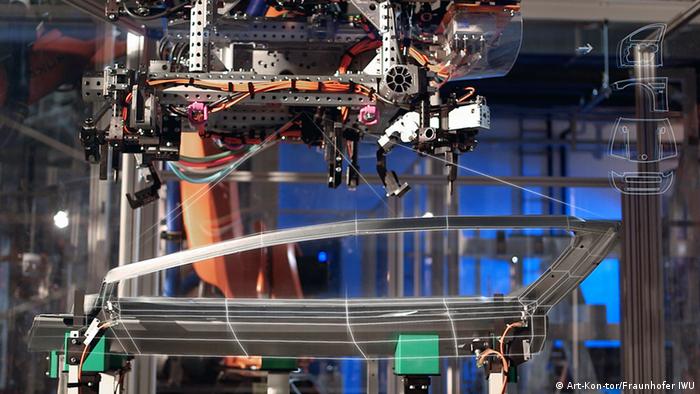

New Machine Concepts

Industry 4.0 opens up on the once gigantic opportunities. “It’s about new customers use to generate through networking. As in private life, too, can be a lot of activities, or even automated, simplified,” says Prokop. Thinking in terms of networking solutions for many companies, however, still new and in need of a change in the angle of view. From the vertical to the horizontal perspective, that is the motto. The machine should not be the sole focus. Rather, they need to be optimally embedded in the operating processes of a company.

So a completely new machine concepts could be created, new assistance systems or solutions for the flow of material and parts tracking. And who could achieve this better than the machine tool manufacturers that are in the middle of the production process at home? “A large field that lies fallow in some areas is still largely and the creativity of the manufacturer’s massively inspiring,” says Prokop.

Better Training Opportunities

The most valuable resource for the German machine tool industry work in all areas of a well-trained, highly qualified and very committed employees, who are proficient in their tasks and with a high level of Motivation. The rapid technical changes in connection with industry 4.0, however, also require new skills of them.

Against this Background, Procopius calls for an urgent initiative for excellence for vocational education and training. This includes strengthening the Image of the vocational training and technical careers. Especially, it is important, however, to secure a sufficient financing of the vocational schools for equipment and training, so that young people can be trained on the latest state-of-the-art.