It is not often that a hardware manufacturer, a glimpse into the kitchen grateful, but tweaker TERW_DAN got the chance to figure out how Gigabyte have motherboards to assemble. He received an invitation from the company for a detailed, guided tour of the Nan-Ping Factory, just outside the capital of Taiwan is located. Remarkably, when the tour was that the making of photos for this one time it was permissible.

A motherboard from Gigabyte begin if pcb. The first machine in the way of board-to-system board provides the pcb of solder paste, after which the second machine, the resistors and the chips with a speed of 10 smd led’s per second on the plate attached. The third machine places the northbridge, the southbridge and the socket, whereby the plate is gradually becoming more on a motherboard begins to appear. After all components on the board sit, follows an extensive and thorough testing of the operation of the motherboard.

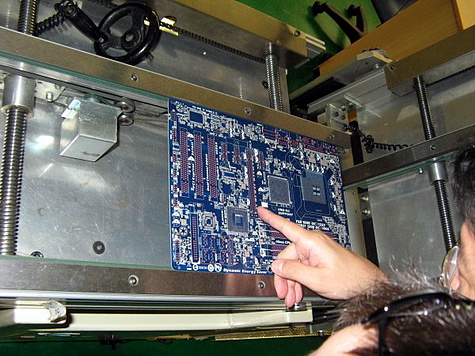

The first inspection is by the staff done. They look at the system board under the magnifying glass errors. If the system board is checked, it will have a sticker with barcode and serial number, and the road will be prosecuted. The next step is a second audit. The motherboard is by five cameras ge lwa nspecteerd, that at a time of eighteen photos of different sections. On average, a thousand pictures of a motherboard. A micro-atx board will be less photos taken. The last step of the testing phase is a so-called circuittest. A special device to test or all of the connections on the motherboard to work.

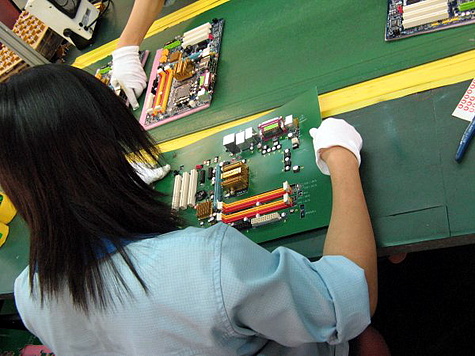

If the board is the testing phase successfully completes, the assembly of the system board continue to be followed with the posting of the bios. A fifth machine programming eight bios chips and place the completed. n chip on the motherboard. The next step in the process is lopendebandwerk. To a band of over 15 meters are under more usb and ps/2 ports, memory slots and ide and sata connectors on the system board secured. Each employee is responsible for placing completed. n part. With a hammer (fits everything  ), the components are firmly seated, and then the motherboard again by a machine. This machine can solder all the components, then the moederplank on a following band is laid, and this again an inspection is undergoing. Employees have a mold in the hands of who on the board is laid, so that at a glance missing parts to be seen. On the same band are also employees with the soldering iron to solder-remnants to take away. Furthermore, the boards with heat sinks equipped, and the whole of a label.

), the components are firmly seated, and then the motherboard again by a machine. This machine can solder all the components, then the moederplank on a following band is laid, and this again an inspection is undergoing. Employees have a mold in the hands of who on the board is laid, so that at a glance missing parts to be seen. On the same band are also employees with the soldering iron to solder-remnants to take away. Furthermore, the boards with heat sinks equipped, and the whole of a label.

The last and final check is the test of the system board. A second mold, and includes a video card and sata cables – only the processor is hand-placed – after which the whole is booted. As a motherboard for the testing process successfully met, it will be forwarded to the packers, which is the small board in the box explains with all the necessary extras such as manual, a drivers cd and the cables. A motherboard that is frowned upon, appears in the testing set. Each board is according to Gigabyte tested separately. It takes two to three days for a motherboard to assemble, to which most of the time in the test.

The full report of Terw_Dan in this topic on Gathering of Tweakers, where all the photos that he has made.