What is cheap is often not made in Germany. Different Beer mats, as the world market leader for such coasters made of wood and the water sits in the black forest.

Coasters are extremely versatile. They are ready when a sought-after telephone number must be listed or if you need out of boredom, something to turn rumknibbeln. Children can look at the map of houses build well with you and drinking buddy to be impressed with a cardboard lid-art pieces. Forgetful hosts, serving you to record the extent of its use and, finally, to protect tables and the drinking-joyful self in front of the Spill by dripping glasses.

And that’s not all, says Karsten Beisert. “There are many possibilities, but can be taught on the coasters advertising messages, to convince the guest, perhaps of something else entirely. And, of course, the revenue of the host is expected to rise.”

Karsten Beisert draws since the end of 2018, the fortunes of The Katz Group

Beisert is since good a half year quasi-the Lord of the beer coasters in the world. More precisely, he is the managing Director of The Katz Group, which has deep in the black forest to the cheerfully babbling River Murg to your seat. Here is the tranquil place way stream is surrounded by wooded hills. The Idyll is ideal for the versatile coasters, because here there is everything you need for the production: wood, water, and energy.

Cheap product “Made in the black forest”

Even though beer caps are in the truest sense of the word, cheap products – a beer cover costs only a fraction of a Cents, and prices are given in thousands of the production takes place for over 100 years, it is precisely here, in Germany, and not in one of the classical low-wage countries.

“The paper industry has always been set up there, where energy and raw materials in the vicinity were,” says Beisert. The people in the black forest, have been living for generations from the wood and therefore, you will also find people who know how to deal with wood.

A beer Mat made of wood pulp Board costs only a fraction of a Cents

“We have here make a few very proud to be the paper champion, the concerns for the quality of the product. Our coasters are a natural product which belongs always dependent on different weather conditions in the production of different and very precise attention needs are.” The quality of the production is constantly monitored in the lab, because it’s as simple as a beer cover also acts – it is a lot of demand already, so that it can accommodate coasters up to 300 percent of its own weight in moisture.

Special machines, which you will not find on the market so

Of course, large machines are necessary, whose cost several million cost. For potential competitors it seems to be in combination with the low price not a big incentive to enter the market. It just takes too long until the cost of such investments can be recouped. So, The Katz Group, controlled about 70 percent of the world market and is Essentially, with other German producers from the Eifel region in the competition.

Early in the Morning every day to deliver multiple Truck about 2-Meter-long tree trunk pieces. A short time later the dull Roar from the debarking drum is evident on the factory premises. Again and again the tree to bounce on tribes against each other while they are whirled like a giant washing machine around. The air is soaked with the smell of fresh wood and resin.

Without the bark, the stems from the drum, from where they are transported by conveyor belt to the next machine, the grinder. Here, the logs are filled in a several meters high funnel and the weight of the developing strains of slow-down in the direction of the grinding stone is pressed.

With the help of a roller, the debarked wood to be defibrated tribes and mixed with water to form a paste

“Here is the entrindete wood is disassembled into its individual fibers,” says Alexander Braun, who is responsible for the production. He is showing the grinding stone in the bottom of the machine. Depending on the desired quality of the wood, a grinding stone is used with a so-called sharpening pattern. “We are cool with spray pipes,” said brown. The water supply cleans the grinding stone-Zone and the shredded wood is warm to 70 degrees, thick liquid, grey wood-pulp.

Around 70 degrees, warm the thick liquid of wood pulp, after he comes out of the grinder

In the next big machine, the mass is pressed to a thin, 130-Meter-long rail, dried, and glued several layers. It is wood pulp paperboard, which is printed in a subsequent work gears, and punched to covers Beer, or beverage coasters created.

In several steps, the web is pressed from wood pulp, is dried in layers, glued

Your own water power provides energy

You can not see it, but these cardboard machine dates back to the end of the 1950s. However, it is been modernized and is today controlled in a control centre electronically. Was invested in 2015 in the modernisation of the two in-house hydro power plants.

“The paper industry is energy-intensive,” says Beisert. Energy is not only a great theme for the Katz Group, but also for Papierfabrik August Koehler belongs to the cat since 2009. “The Koehler group has set itself the target in the year 2030 to produce the energy itself, which is to be used.” In way stream, the river Murg helps now. Two on-site turbines to supply more than half of the current that is needed here for the beer lid production.

The lower paper web is sprayed with starch and with the coming from the top track bonded to the

The world market leader with big plans

The extent of today’s beer Mat production, which accounts for the main revenue of the Katz Group, was over 300 years ago, is not foreseeable, when Johann Georg Katz acquired in way stream, a sawmill, and so the Foundation stone for today’s company put. Not until 1903 that one of his descendants began with the industrial production of Beer mats. Today, The Katz Group is to provide the three billion beermats in the year. Will be delivered in the whole world, says Beisert.

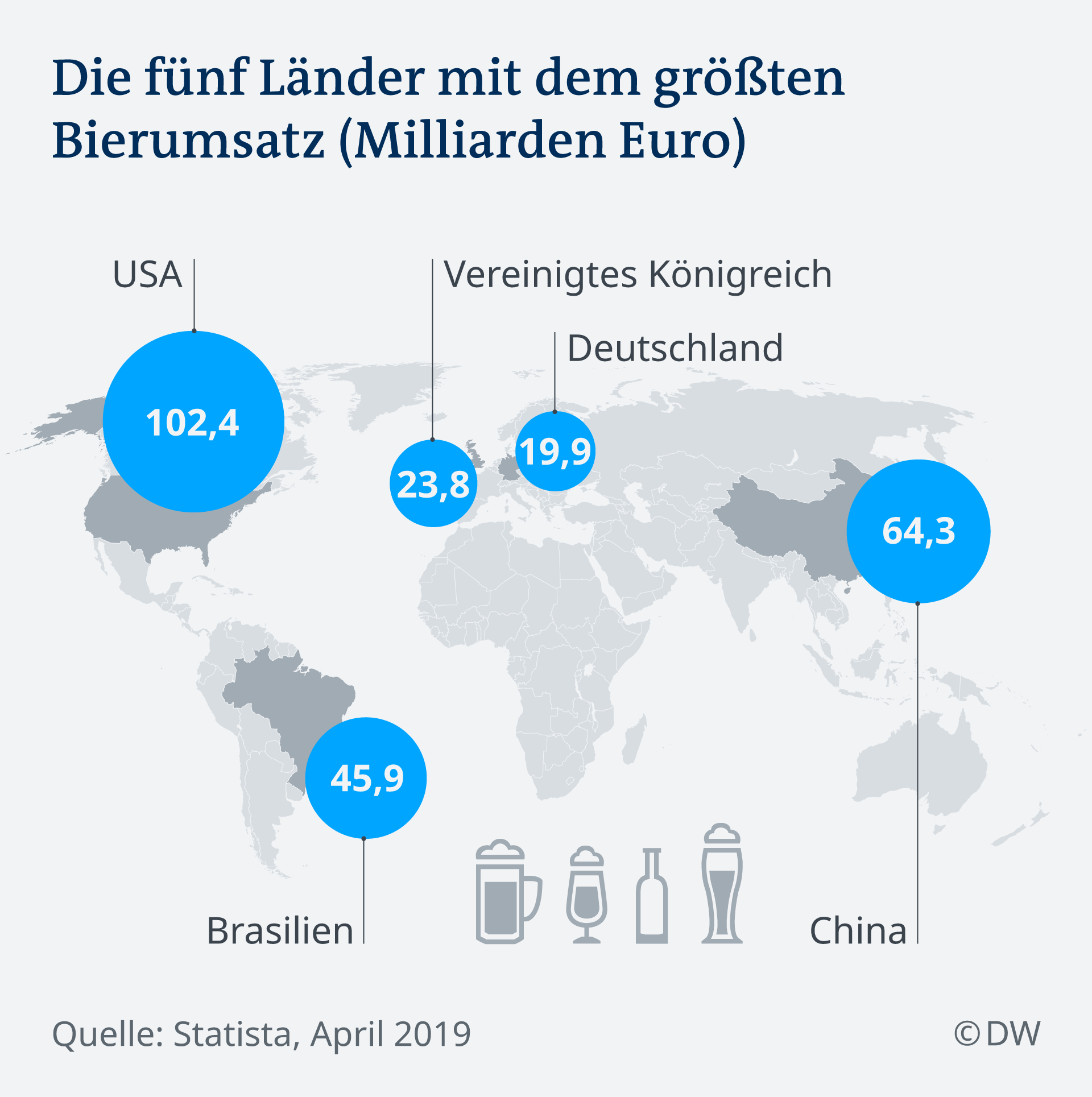

Several subsidiaries help. The Largest is in the United States, where in two production sites will also be drinks coasters are produced. In addition, there are sales offices, for example, in Singapore, and the United Kingdom. However, there are not drinks coaster yet in any country as often as in Germany, the UK or the USA. According to Beisert, you should not make in the future, also in Uruguay, or Siberia drinks directly on the table.

An employee examines with a magnifier, whether the print and color quality

Beer lid 3.0

More and more customers, the Germans want to win in order to upgrade the beer cover a small multi-talent. It is not enough to just have moisture to absorb. For the eye new forms and colors are created. For the nose brought scents, the cups of beer smell to make in old pubs competition on the cover-up.

The game engine printed Codes to use via Smartphone, via the online sweepstakes or other promotions can be worn to the customers. And for the perception of over-the-ear “can serve as a built-in micro chip,” says Beisert, “to a melody or piece of information can be played back”. For the drinks manufacturer, has ordered the beer lid, another way to advertise.

After the coasters were punched, they are stacked, Packed and in all the world sent

Even if The Katz Group is planning the world with this omnipotent, fragrant, tinkling, shimmering, and surfing to give beer lid – it is also necessary to explore new fields of business.

Search for new legs

A potential new customer Beisert is the automotive industry. Because there is now strong at lightweight, he hopes that The Katz Group is able to prevail with solutions from wood pulp cardboard against plastic products.”We are in negotiations and want to naturally bring to a successful conclusion. It is, for example, blinds and door panels for our product as a carrier material offers.”

Wood pulp cardboard is lightweight, extremely absorbent and relatively stable

Such new fields of business to build, is expected to be a good idea. For anyone who does not know whether beer lid got one day in the sight of the environmentalists, who think that you can take home without special coasters drinks, and therefore, the production of beer lids may be as superfluous as the production of paper cups for coffee or drinking straws made of plastic.

In 2009, The Katz Group, on the verge of bankruptcy, partly because of the decline in beer consumption. The is now risen again and the forecasts continue to go up.