Boeing said its planes were after a Software Update and hundreds of test flights again for sure. What errors have fixed the engineers exactly?

In the case of the Boeing 737 MAX changes little, in the Cockpit, but some of it in the manual

On Thursday, the US aircraft manufacturer Boeing announced that it has completed the Software Update to the entire fleet of 737 MAX aircraft. The company have also completed 207 test flights with more than 360 hours of flight time.

The aircraft type was safe to go back. Problems that led to the crash of Lion Air flight 610 in October 2018, and of Ethiopian Airlines flight 302 in March 2019, would not occur in the future.

Now the aviation authorities check, whether the machine may start again soon.

What led to the crash?

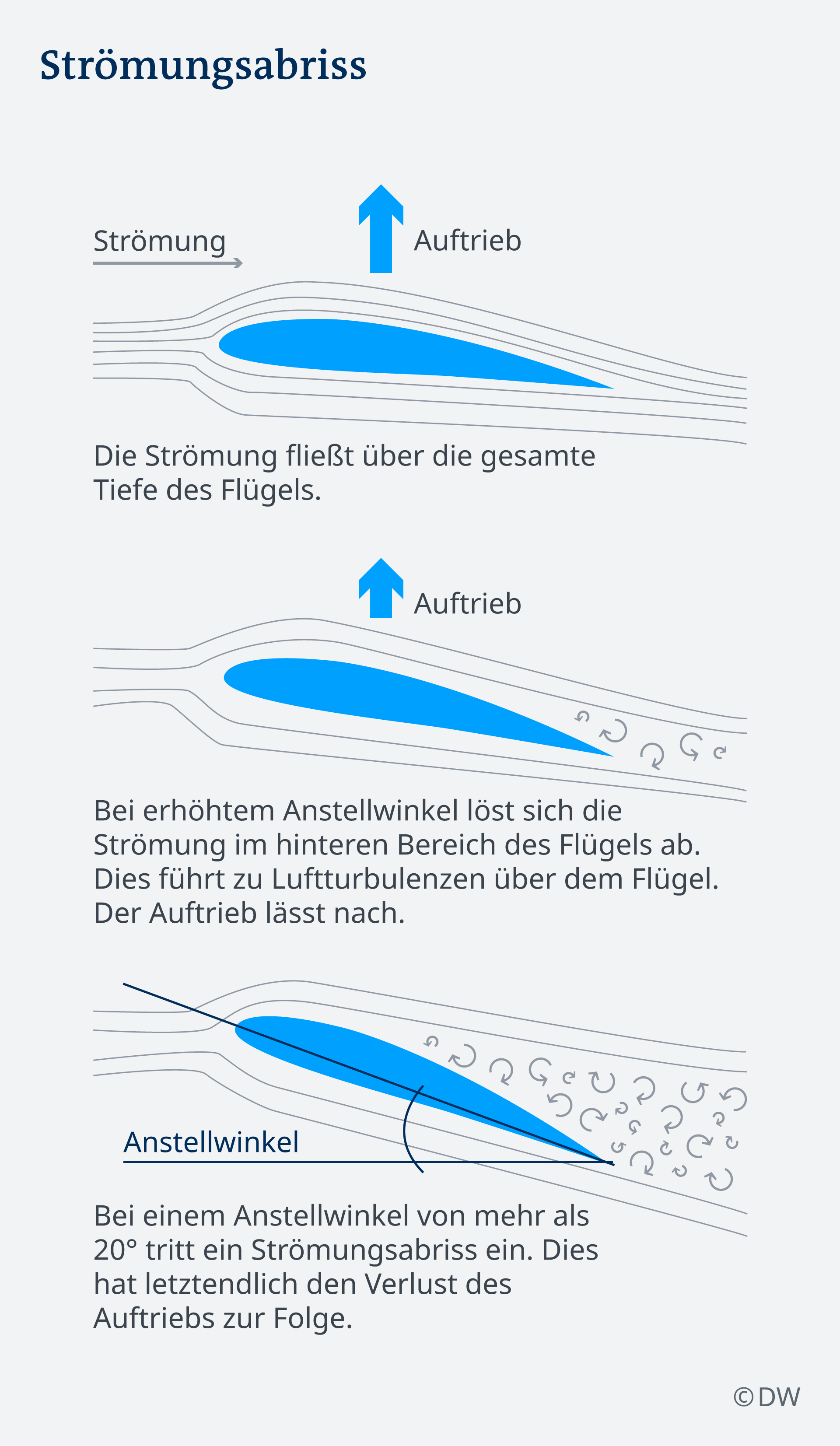

The crashes have declined probably due to the fact that for the 737 MAX aircraft developed control system called the Maneuvering Characteristics Augmentation System (MCAS) received incorrect data from a Sensor that measures the angle of attack of the wing to the air stream.

The angle of attack is crucial for the lift of the aircraft. He is too low, the plane into a descent. He is too high, the demolition of the rear part of the wing to a flow. Then it can happen that the Pilot loses control of the plane and it falls like a stone.

Such an impending flow, the MCAS is intended to prevent demolition by pushing the nose of the aircraft with the help of the Elevator to the bottom.

It did in the two accident cases, however, so strong that the pilots had no Chance to gain height. It managed to put the aircraft in the climb, because the MCAs crashing down and against contributed to the aircraft at the end.

More: Why is Flow separation in aircraft is so dangerous

First Problem: Plane Geometry

Boeing had introduced the MCAS System, to solve the deep, structural Problem with the plane geometry. The 737 MAX had to get a bigger and heavy engine than originally thought. It was quieter and saved fuel.

The engine had to be attached because of its size but a bit further forward and higher on the wing. This led to a change in the aerodynamics. Thus, the aircraft was prone to a phenomenon that otherwise, especially of Supersonic military aircraft, with the wings of the arrow, and form is known: The so-called Pitch-Up.

This is a special Form of stall, which can occur at any speed. This danger should be averted MCAS through early Intervention.

For MCAS should be able to initially readjust the angle of attack of the wing to 0.6 degrees. In fact, MCAS was configured so that it could correct the angle by up to 2.5 degrees, which corresponds to about half of what was in the type of aircraft to be physically possible. Bottom line: used for end of tax powers had to be far-reaching.

Since the Geometry of the aircraft is not changed, remains the MCAS continue to be in operation, and ensures that no flow occurs demolition. But for all the other problems, namely, what were the reasons for the crashes, the engineers have found solutions.

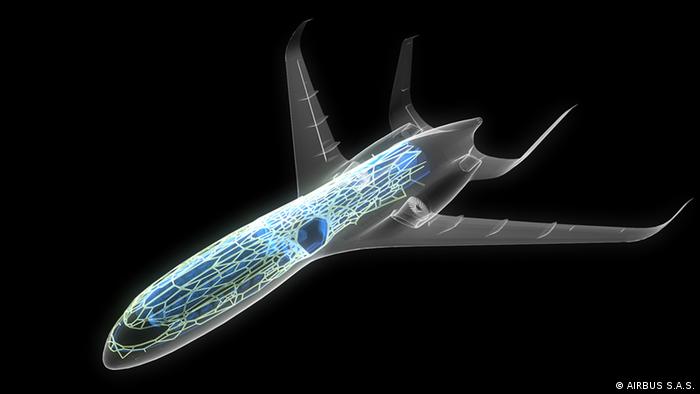

So we fly in the morning: The aircraft carrier for the city – An airport for the future

The huge engines of the plane are very eco-friendly, but hanging far to the front, and are heavy.

Second Problem: Who decides – robot, or a Pilot?

In both crashes, the robot had to be decided. Obviously, the pilots were not able to turn off the MCAS, in order to get it back under control.

While they had the chance, the MCAS paralyze, however, this would also means that the electronic control system of the Elevator would also be failed.

While there is not as a fall-back option is still a manual control, but it is in all flight situations, strong enough to keep the plane stable. So the Pilot would have to turn under the circumstances, the electronic support – which would in turn reactivate the MCAS.

In the case of the two crashes, it was not even The pilot had not turned off the electronic control and tried desperately to bring the plane back up.

The solution, implemented by Boeing now, disempowered the MCAS to a large extent:

Pilots can overcome – if necessary – MCAS through an intuitive strong Pull on the control stick.

Third Problem: What is the Sensor you can’t trust?

The MCAS receives various sensor data and calculates therefrom, in which flight the aircraft is just: speed, altitude and angle of attack to the air stream.

Basically, all Sensors are designed in an airplane twice, so that the failure of one sensor still other works. Originally MCAS was designed so that the Pilot gets an error message, if the two angle-of-attack Sensors provide conflicting data.

More: Boeing failed to mention the Problem with the 737 MAX

The accident pilot will soon be ready to start again.

However, this warning message only worked if there is an additional display monitor was installed in the Cockpit and did not belong to the base version of the aircraft.

Only about a fifth of the delivered aircraft are equipped with it. The crashed aircraft had no Monitor. That’s why the pilots could not detect that the Sensors provided incorrect data.

Boeing’s solution: The electronic control system of the aircraft matches in the future, the data from the two angle of attack Sensors. There should be a flap between the two – in the case of the retracted Wing – a difference of more than 5.5 degrees, can no longer intervene, the MCAS in the future.

In addition, Boeing now offers for all the planes for free, the retrofit with the previously paid-for monitor system, the fails with wrong sensor data Alarm.

Fourth Problem: training and Information

It is unclear whether the accident pilots were trained on the handling with the MCAS is sufficient and in General knew what you can do in the Situation, may still be had, in order to save the plane.

What is the Situation intensified: On the function of MCAS has not been indicated in the applicable manual for the aircraft type. The engineers were obviously assumed that the MCAS will work automatically.

Under normal conditions, the pilots from MCAS remember nothing. Appropriate instructions would have confused everyday pilots, only more so, the logic of the manufacturer.

This will not be the case in the future: as of now, Boeing takes in dealing with MCAS in the training program for 737 pilots, the manual will be supplemented with a detailed Chapter.

The US aviation authority, FAA is currently reviewing whether the conditions for re-admission of flight operations are given. At the earliest, in a few weeks, it could give a green light.

Other international regulatory authorities need probably for a little longer until you can agree to the technical Details and also completed training programme for pilots. Until then the Boeing 737 MAX are expected to fly-machines, but also to other continents.

More: The planes of tomorrow